Flinks:

https://www.blbender.com

Introduction:1.The principle of the turning wire bending machine is that the line does not turn bur the head turn,Lightweight head structure, to ensure rapid and stable production. 2, wire feed and arm, both separate and cooperate, when turning the head really do not

| (Model No.) | BL-3D-61600 | |

| No. of Axis | 6Axis | |

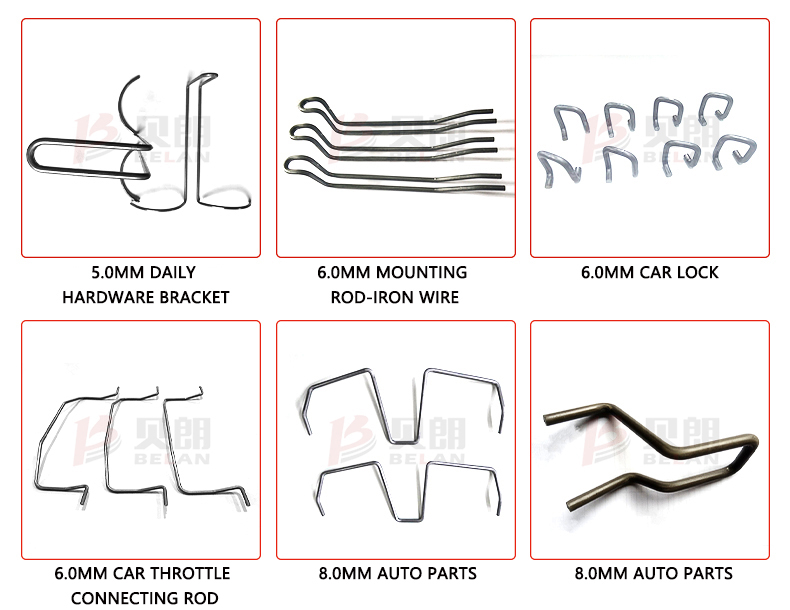

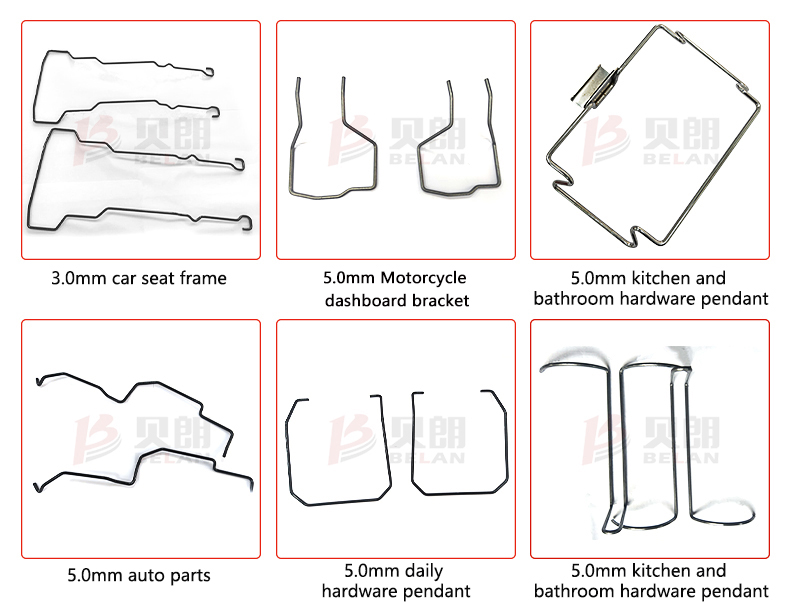

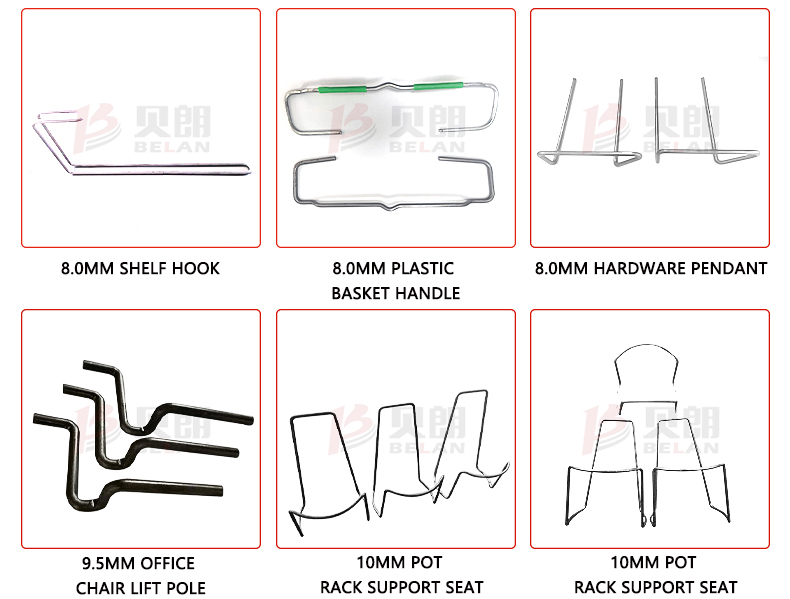

| Input OD of Wire | hard material Φ6.0~φ10.0mm | soft material Φ8.0~φ16.0mm |

| No. of Feeding Round | 4sets | |

| Power of Wire Feeding Motor | 15.0KW | |

| Power of Turning Motor | 4.4KW | |

| Power of Wire Cuter Motor | 7.5KW | |

| Power of Moving Motor | 0.75KW | |

| Power of Angle Control Motor | 0.4KW | |

| Weight of Machine | 4200KG | |

| Input Power | 380V/50HZ/3PH | |

| Size(L*W*H) | 3960mm X 1670mm X1700mm | |

1.The principle of the turning wire bending machine is that the line does not turn bur the head turn,Lightweight head structure, to ensure rapid and stable production.

2, the computer Quick start-up and shut-down,operation simple, convenient, vivid. The computer interface can be produced while adjusting the speed while changing the program.

3. High-speed motors imported from Japan and speed reducer imported from Germany are used in the configuration, and the production speed is more than 25% higher than that of similar products in the domestic industry.

4, wire feed and arm, both separate and cooperate, when turning the head really do not turn the line, can achieve smaller outer diameter arc and multi-circle product forming.

5. The production can achieve no change in the Angle at the slowest speed and better production stability.

6. Bearings, gears and other important parts are imported from Taiwan, one year warranty. The equipment is durable and reliable.

7, High precision, can do 6.0-18.0 mm wire diameter range of wire molding products, error to 0.1 mm

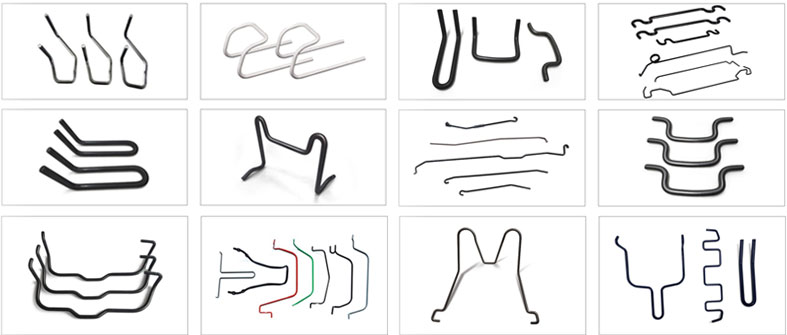

Products Are mainly Used In Automobiles, Kitchenware, Garden Tools, Supermarket Shelves, Furniture, etc.